Emkhiqizweni wesimanje, ukusebenza kahle kanye ne-automation yizici ezibalulekile ekuqinisekiseni ukukhiqizwa kwezimpahla okubushelelezi futhi okungabizi kakhulu. Lokhu kuyiqiniso ikakhulukazi embonini yokudla neziphuzo, enesidingo esiqhubekayo semikhiqizo yekhwalithi ephezulu kanye nezinqubo zokukhiqiza eziphumelelayo. Enye yezindawo lapho i-automation ibe nomthelela omkhulu isekukhiqizweni kweImishini yokugcwalisa i-BIB.

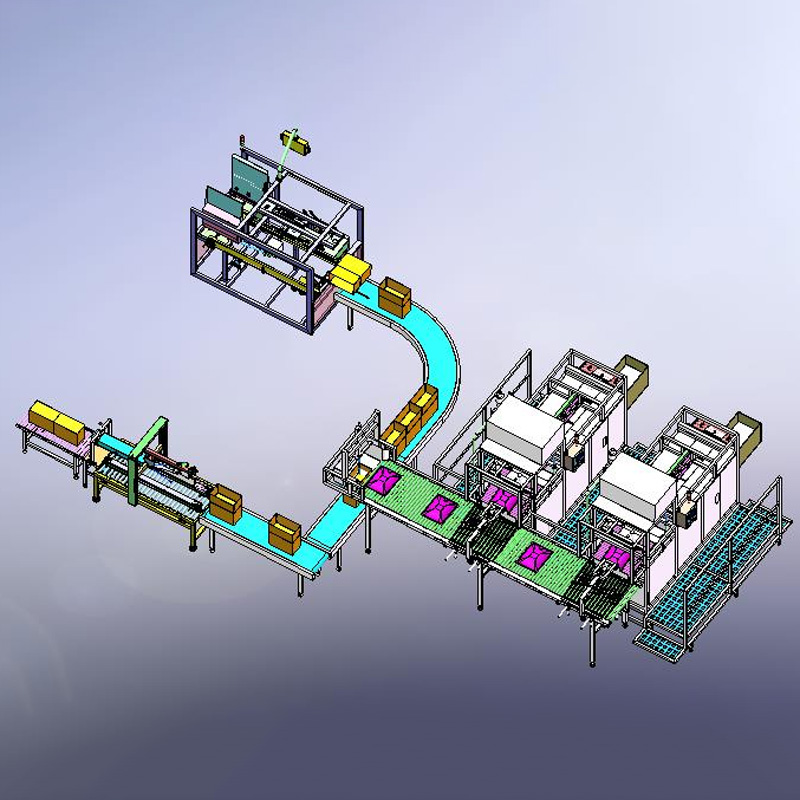

IUmshini wokugcwalisa i-BIBumugqa wokukhiqiza uyingxenye ebalulekile yokupakishwa nokugcwaliswa kweziphuzo ezifana nejusi, iwayini neminye imikhiqizo ewuketshezi. Yonke inqubo kusukela ekugcwalisweni kuya ekufakweni kokugcina izenzakalela, inciphisa ukungenelela okwenziwa ngesandla kanye nezindleko kuyilapho kunciphisa ngokuphumelelayo amazinga amaphutha nezingozi. Leli zinga lokuzenzakalelayo lishintsha ngokuyisisekelo indlela imishini yokugcwalisa ye-BIB ekhiqizwa ngayo, ikhulisa ukusebenza kahle kanye nokukhiqiza. Ulayini wokukhiqiza womshini wokugcwalisa we-BIB uqukethe uchungechunge lwezinqubo ezihlobene ezisebenza ngaphandle komthungo ukuze kuqinisekiswe ukugcwaliswa nokupakishwa kwesiphuzo okusebenzayo nokunembile.

Isinyathelo sokuqala emgqeni wokukhiqiza ukugcwalisa imikhiqizo ewuketshezi ezikhwameni. Yilapho okuzenzakalelayo kungena khona, njengoba inqubo yokugcwalisa ilawulwa ngokunembile ukuze kuqinisekiswe amazinga okugcwalisa anembile futhi angaguquki. Lokhu akunciphisi nje kuphela ubungozi bokumoshakala komkhiqizo kodwa futhi kuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zekhwalithi ezidingekayo.

Uma izikhwama zokugcwalisa zivaliwe, zihamba emgqeni wokukhiqiza ukuya esigabeni esilandelayo, okuhlanganisa ukuvala nokupakisha izikhwama zokugcwalisa. Ngokunjalo, i-automation idlala indima ebalulekile kule nqubo njengoba imishini ifakwe ubuchwepheshe obuphambili bokuvalwa nokupakisha ukuze kuqinisekiswe ukubekwa uphawu okuphephile nokuhlanzekile ezikhwameni. Lokhu kubalulekile ekugcineni ubuqotho kanye nobusha bomkhiqizo, ikakhulukazi eziphuzweni ezibolayo.

Njengoba izikhwama ezigcwalisiwe nezivaliwe zihamba emgqeni wokukhiqiza, zidluliselwa ngokuzenzakalelayo esigabeni sokugcina sokupakisha, lapho zifakwa emabhokisini ukuze zisakazwe futhi zigcinwe. Inqubo yokupakisha ezenzakalelayo iqinisekisa ukuthi izikhwama zipakishwa ngobunono nangokuvikelekile emabhokisini, zilungele ukuthunyelwa kubathengisi noma kubathengi. Leli zinga le-automation aligcini nje ngokusheshisa inqubo yokupakisha kodwa futhi linciphisa isidingo sokuphatha ngesandla, ngaleyo ndlela kuncishiswe ubungozi bokungcoliswa komkhiqizo kanye nokulimala.

Enye yezinzuzo eziyinhloko zomugqa womshini wokugcwalisa ozenzakalelayo we-BIB ukuncishiswa okukhulu komsebenzi wezandla nezindleko ezihlobene. Ngokwenza lula izinqubo zokukhiqiza kanye nokunciphisa isidingo sokungenelela okwenziwa ngesandla, abakhiqizi bangafinyelela amazinga aphezulu okusebenza kahle nokukhiqiza, ekugcineni basindise izindleko futhi bathuthukise inzuzo. Ngaphezu kwalokho, ukuzenzekelayo komugqa wokukhiqiza kunciphisa ingozi yephutha lomuntu, kuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nekhwalithi edingekayo kanye namazinga okuphepha. I-automation ye-Umshini wokugcwalisa i-BIBumugqa wokukhiqiza ubuye uthuthukise ukuphepha okuphelele kwenqubo yokukhiqiza. Ngokunciphisa isidingo sokuphatha imikhiqizo mathupha, ingozi yezingozi nokulimala emsebenzini ingancishiswa kakhulu. Lokhu akugcini nje ngokudala indawo yokusebenza ephephile kubasebenzi, futhi kusiza abakhiqizi ukuthi bahambisane nemithetho eqinile nezindinganiso zokuphepha.

Isikhathi sokuthumela: May-24-2024